WA_ZV Model

Contact Number: 0769-22236227

Related products

The W series is a highly stable, efficient, and convenient high-end control system configured for high-end fully automatic rotary template machines such as head rotation and needle bar rotation; Adopting a bus driven system, it is easy to achieve high-speed synchronous control of needle shuttle rotation, with high synchronization accuracy and fast response; The W series has rich scalability, and can be customized and integrated with various processes such as laser cutting, rotating cutter bag opening, automatic feeding, automatic receiving, automatic shuttle changing, etc., achieving perfect sewing results in any sewing direction while improving production efficiency with multiple uses. Its main functions are as follows:

- Needle shuttle bus type high-voltage synchronous servo, with greater force, higher synchronization accuracy, faster response, and a maximum speed of up to 4000 rpm; Both electronic and mechanical handwheel following debugging methods are supported.

- The up and down rotation axis bus synchronous stepper drive achieves unified and perfect stitching in any direction, intelligently recognizes machining trajectories such as reinforced inverted needles, herringbone seams, and corners, and plans synchronous motion of the rotation axis without the need for additional code control.

- Supports high-speed full closed-loop stepper motor presser foot, automatically tracking spindle position, stable and powerful swing

- Supports high-speed full closed-loop stepper motor thread cutting, with fast thread cutting action simulation debugging, stroke testing, and modification functions

- Supports functions such as lasers, cutting knives, point pens, and their auxiliary devices such as cylinder or motor lifting, rotating cutting knives, etc

- Dozens of universal template machine input functional components can be added, such as wire break detection, bottom line detection, air pressure detection, oil level detection, laser head position detection, template in place detection, etc

- Dozens of universal template machine output functional components can be added, such as wire loosening, wire pulling, electronic wire clamping, blowing, top plate, oil supply, laser fan, laser blowing, machine head lifting, etc

- Scalable up to 512 expansion IO and 16 auxiliary axes

- Customized programming function easily completes automatic material receiving, feeding, and various customized processing processes

- Support for benchmark free function, easy to import the same pattern into any machine for direct use, without the need to adjust the position

- Equipped with a 7-inch true color LCD touch screen panel, the interface is simple and easy to operate

- Supports multiple languages such as Chinese, English, Vietnam, Myanmar, Indonesia, Turkey, Russia, and supports voice broadcasting function

- Support importing multiple formats of files from USB flash drives, such as SDT, PLT, DXF, TZF, etc

- Memory can store up to 999 machining files, with no limit on the number of stitches per machining file

- Parameter management function: mechanical parameters, user parameters, controller parameters, drive parameters, etc

- File management functions: creating new patterns, editing patterns, quick editing, importing and exporting patterns, RFID writing, etc

- System recovery function: one click parameter recovery, parameter import and export, one click upgrade, module upgrade, etc

- IoT functions: remote device monitoring, system upgrade, file transfer, system recovery, progress and processing statistics, etc

- Password management function: multi-level password control, dynamic or static phased unlocking

- Multifunctional software tools: such as plate making software, parameter editing software, self programming tools, etc

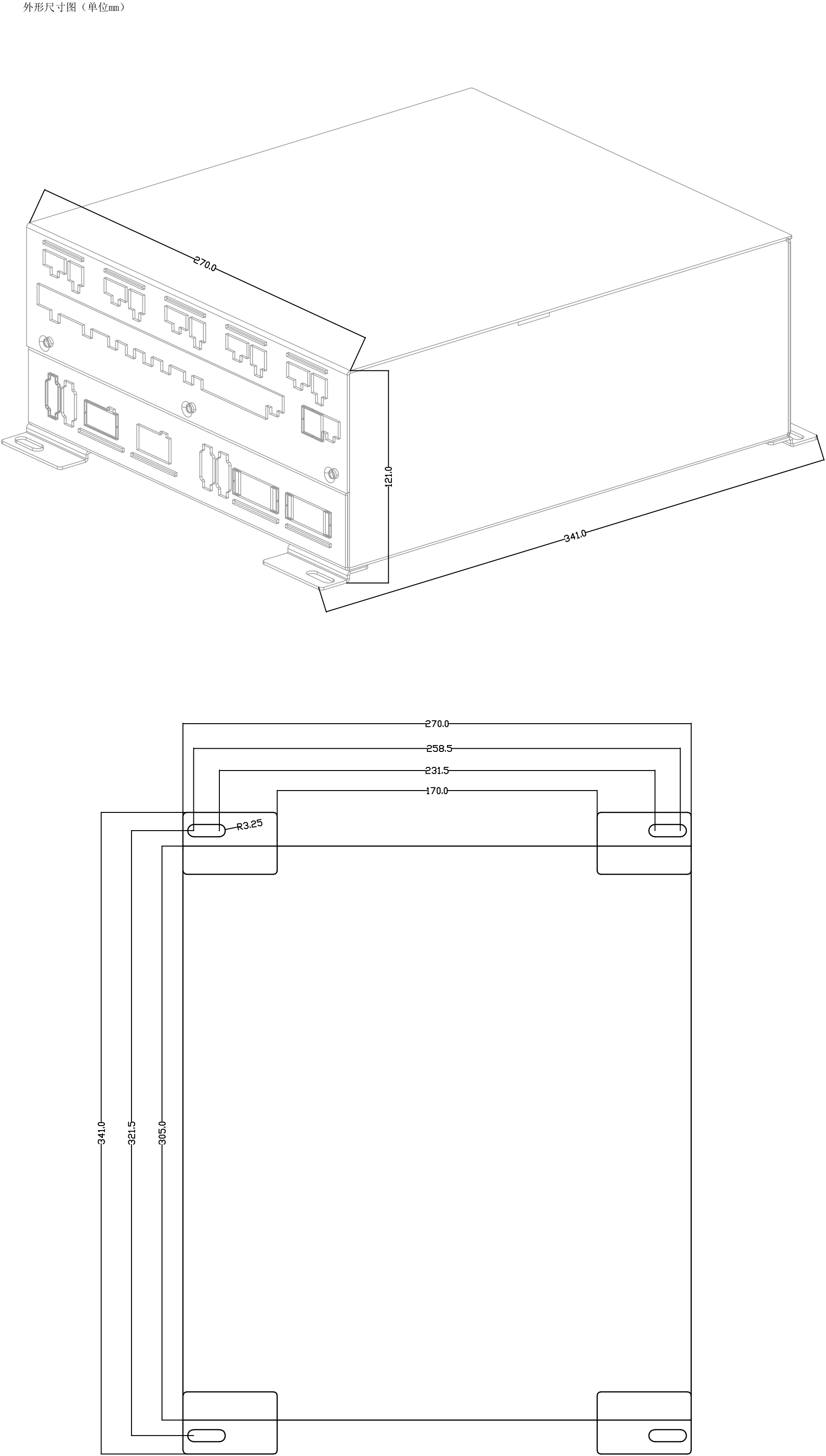

W series parameter specifications

|

Working voltage |

AC190V-240V |

|

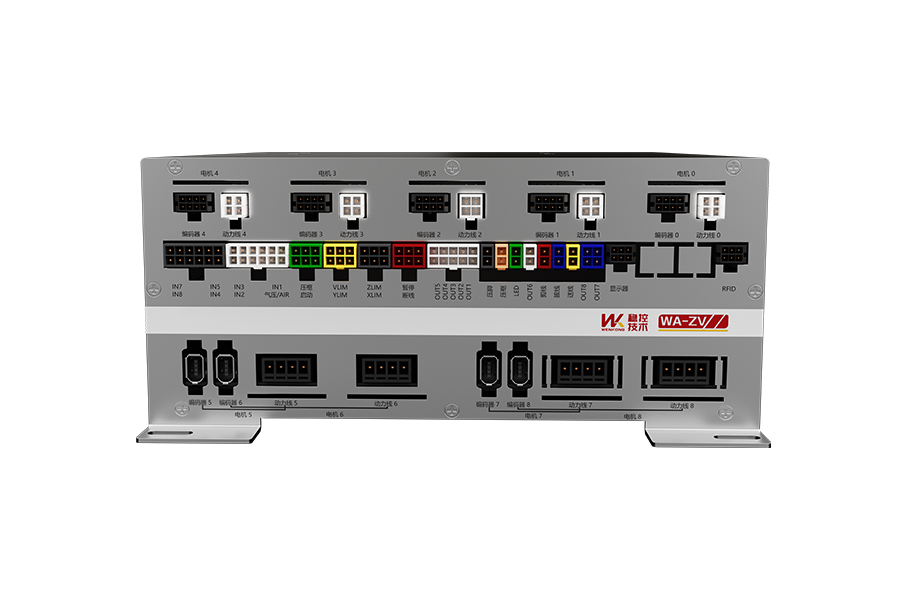

Servo axis |

The chassis supports a maximum of 4 high-pressure servo axes and can be expanded to 16, supporting multiple specifications of encoders |

|

Stepper axis |

The chassis supports up to 6 closed-loop stepper axes and can scale up to 16 |

|

Input port |

In addition to fixed purpose inputs, 13 configurable outputs are configured, and up to 256 outputs can be expanded externally |

|

Output port |

In addition to fixed purpose outputs, 12 configurable inputs are configured, and up to 256 inputs can be expanded externally |

|

Display screen |

5-inch, 7-inch true color LCD touch screen |

|

Template recognition |

RFID identification of the chassis and barcode identification of the display screen |

|

Maximum speed |

4000 rpm |

|

Maximum storage |

999 processing files |

|

Number of pattern needles |

unlimited |

|

Needle pitch |

0.05-50.0 mm |

|

Electronic handwheel |

Configure an electronic handwheel interface that is scalable |

|

USB flash drive |

Support for importing and exporting pattern files, upgrade packages, and parameter files from USB flash drives |

|

WIFI module |

Configure wireless network modules, support remote management, monitoring, production statistics, and other IoT functions |